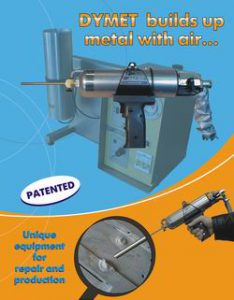

The DYMET model 423 is designed for the deposition of aluminum, zinc, copper, nickel, tin, lead metal coatings. It can be operated manually or installed in automated and robotic systems. It is also capable of sand-blasting surfaces.

Specifications

Maximum compressed air input pressure 12 bar (170 psi)

Compressed air consumption 0.3-0.4 m3/min

Compressed air purity free of water and oil

Compressed air operating pressure

(inside Spraying Gun DM45) 5 – 8 bar (70-120 psi)

Compressed air operating temperature

(in the input of the nozzle) 200 – 600 °C

Power supply:

One-phase alternate current of 50±1 Hz and 220 V

Maximum power consumption 3.3 kW

Noise level in operation without shielded box not exceed 75 dB

Powder consumption 0,1-0,8 g/sec

Time required to reach operating condition no more than 10 seconds

Dimensions of the equipment :

Rack assembly – 550х260х480 mm

Spraying Gun (with handle) – 450х80х175 mm

Spraying Gun (without handle) – 450х64 mm

Total mass of the equipment – 20 kg

Spraying Gun (with handle) – 1,7 kg