Gas dynamic spraying equipment is applied to spray various metal coatings on the base of aluminum, copper, zinc, nickel, lead, tin, babbit. Deposition of iron, cobalt, vanadium and some other metals is also possible.

Coating types

Metal coatings, applied by cold metal spray , are used for various purposes like:

- restoration of form and size of metal parts;

- electric contact pads deposition to metal, glass and ceramic;

- restoration of casting flaws and mechanical defects;

- gas- and liquid-tight sealing (hermetic sealing);

- friction protection (restoration of sliding bearings);

- corrosion protection;

- seizure protection (anti-seizure coatings);

- spark protection (anti-spark coatings);

- decoration.

Basic coatings properties

- high adhesion (30-80 MPa);

- high cohesion (30-80 MPa);

- uniform coating structure;

- low porosity (1-3%);

- high electric conductivity between coating and substrate;

- any coating thickness (from 10 microns up to 10 cm);

- coating surface roughness Rz = 20-40;

- coatings may be machined by any mechanical operation;

- coatings may be deposited to any metal, glass and ceramic substrate.

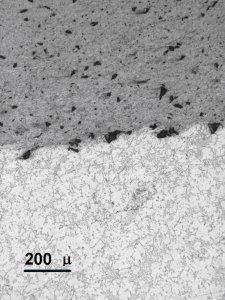

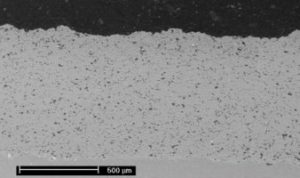

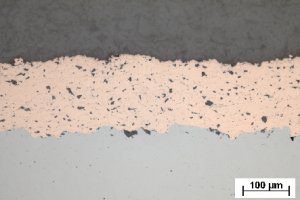

Structure of coatings

Coatings represent uniform dense layer of compacted plastically deformed metal particles with inclusions of impinged ceramic particles.

Ni coating at steel.

Cu coating at steel

Al coating at steel interface.