for manual and cnc operation, long time work, Warranty 24 months, for EU/US market

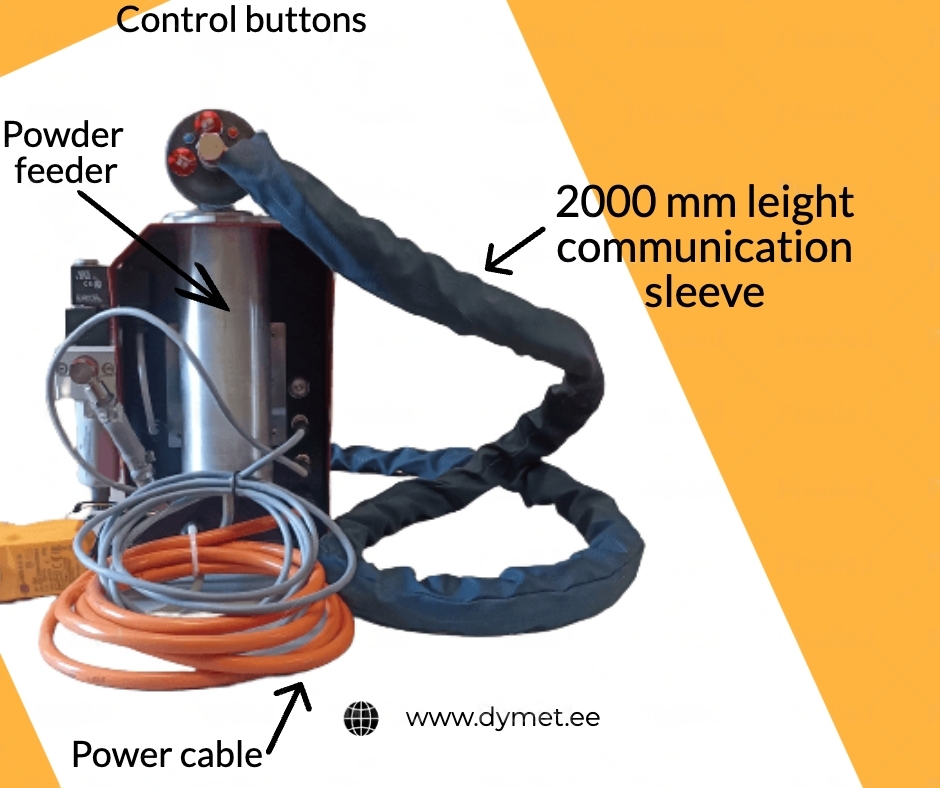

The CSM 108.2 is a lightweight (only 8.5 kg) and mobile solution for applying metal coatings using Dynamic Metal Fusion technology. By accelerating metal powders (e.g., zinc, aluminum, copper, nickel, tin) to speeds up to 800 m/s with compressed air, it enables high-adhesion coatings without thermal impact on the substrate.

Key Features:

-

Single-phase power: 230 V / 16 A

-

Compressed air: 6–8 bar, 400 l/min

-

Operating temperature: 100-600 °C

-

Suitable for manual and CNC operations

-

Warranty: 24 months

Applications:

-

Local galvanization after cutting

-

Restoration of bearing seats, shafts, hydraulic cylinder rods, and printing press rollers

-

Sealing leaks in cooling and air conditioning systems

-

Repairing aluminum wheels from scratches and dents

-

Restoring aluminum molds for plastic casting

-

Applying coatings on glass surfaces

-

Scientific research and material testing

Advantages:

-

Low-temperature process preserves base material properties

-

High adhesion and low porosity

-

Composite coatings with enhanced hardness, thermal resistance, and corrosion protection

#ColdSpray #DynamicMetalFusion #CSM1082 #MetalRestoration #AluminumRepair #HydraulicCylinderRepair #PrintingPressMaintenance #GlassCoating #CompositeCoatings #MaterialScience #CorrosionProtection #LightweightEquipment

- Precise Temperature Control

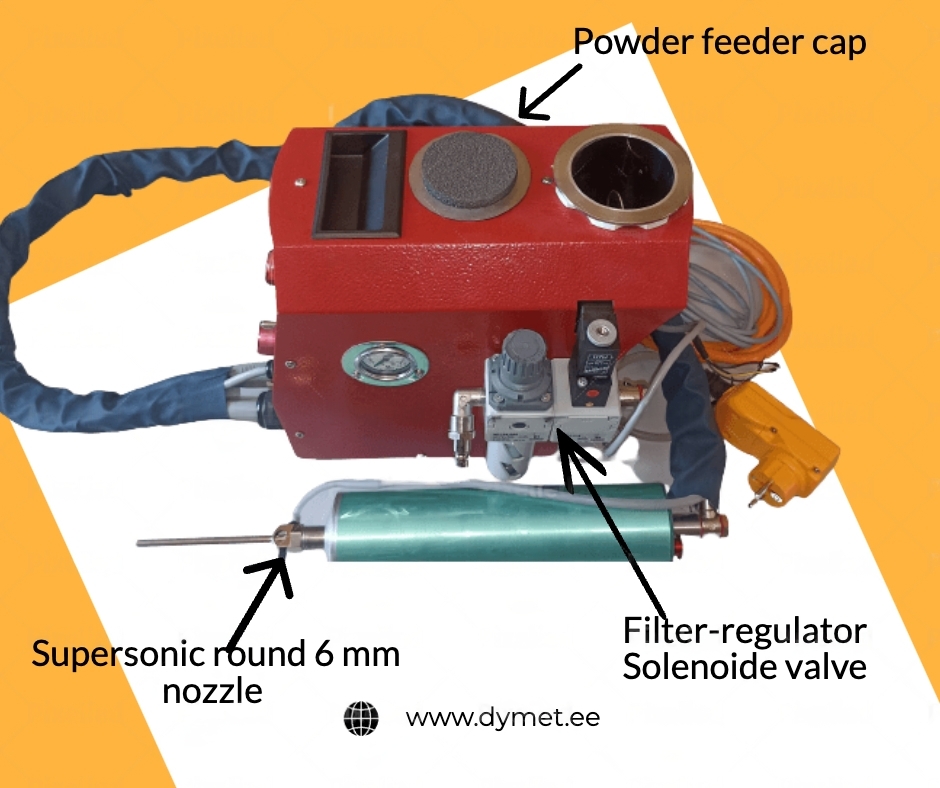

- Automatic Gas Supply via Solenoid Valve

- Pressure Adjustment

- Gas Filtration

- Pressure Gauge

- Additional Electrical Circuit Protection

- High-Quality European, Japanese, and Chinese Components

- Cabel control

Customers :

Florida International University, Plasma Forming Laboratory, Cold Spray and Rapid Deposition Lab